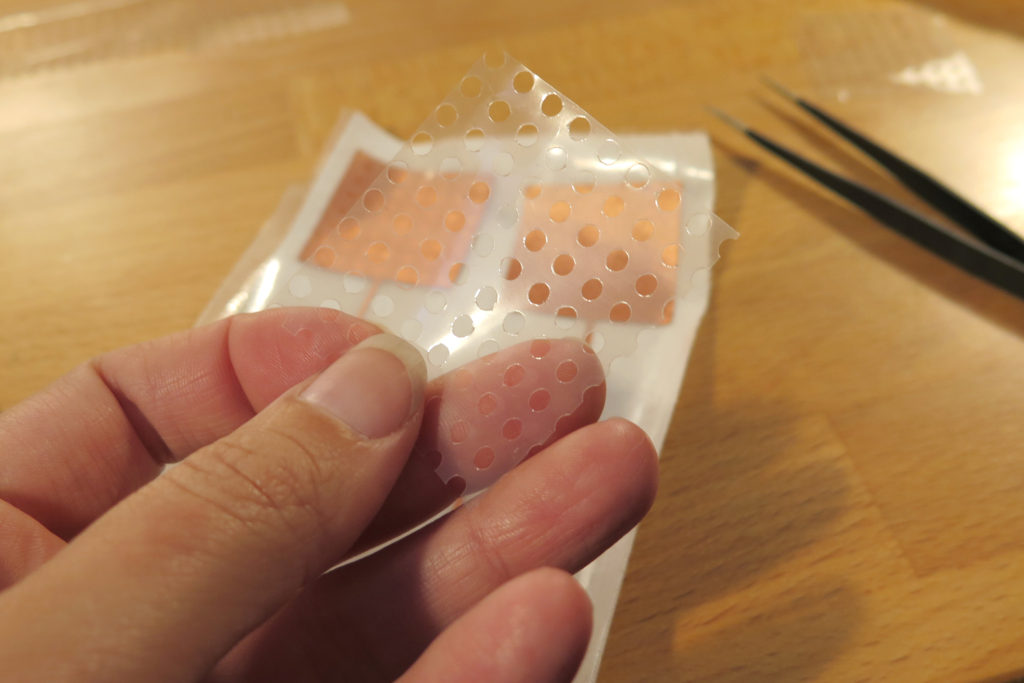

Various nets have worked for some items, such as the cuttable switch, but not for others. Instead of using a plastic net, heat-resistant silicone is currently being tested. I see this being advantageous for various reasons:

- Able to have control of the openings in the net pattern

- Various thicknesses of silicone are available

- silicone is heat-resistant

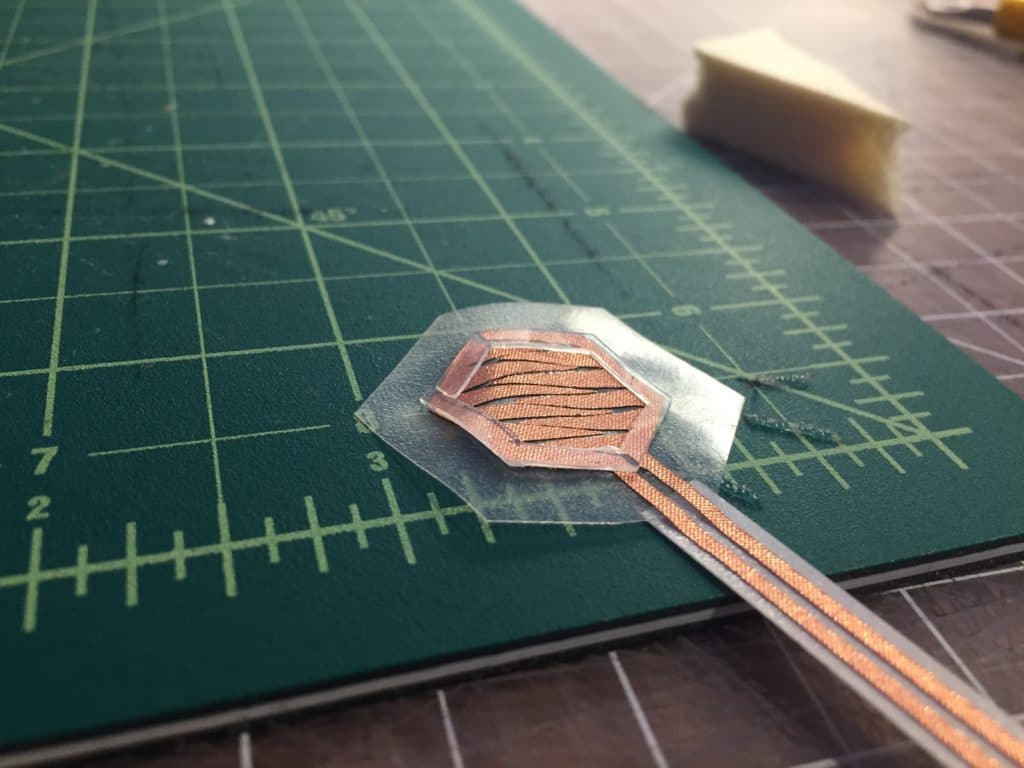

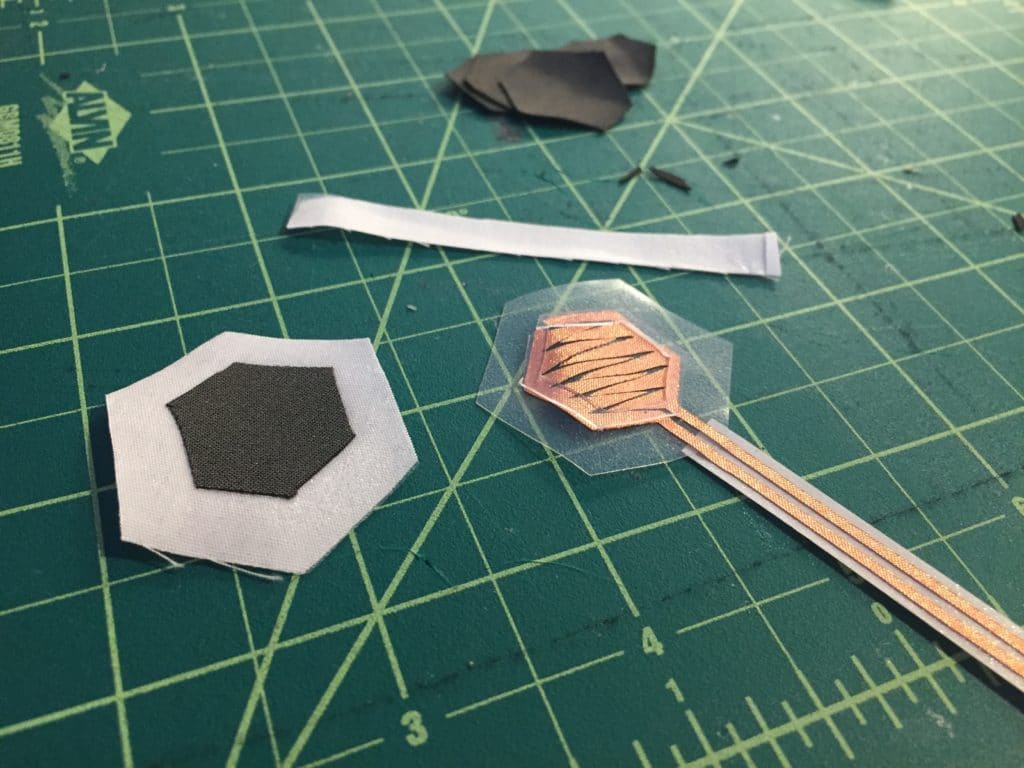

Hexagon Pressure-Activated FSR

The search for a good way to create a pressure-activated FSR for the kit is still underway. The existing hexagon switch design was tested as an FSR and fitted with a simple border of silicone to test as a spacer for a pressure-activated FSR.

Did it work? No. I suspect a spacer border that thin would only work if the materials it was attempting to separate were stiff rather than having the ability to sag and flex so readily.

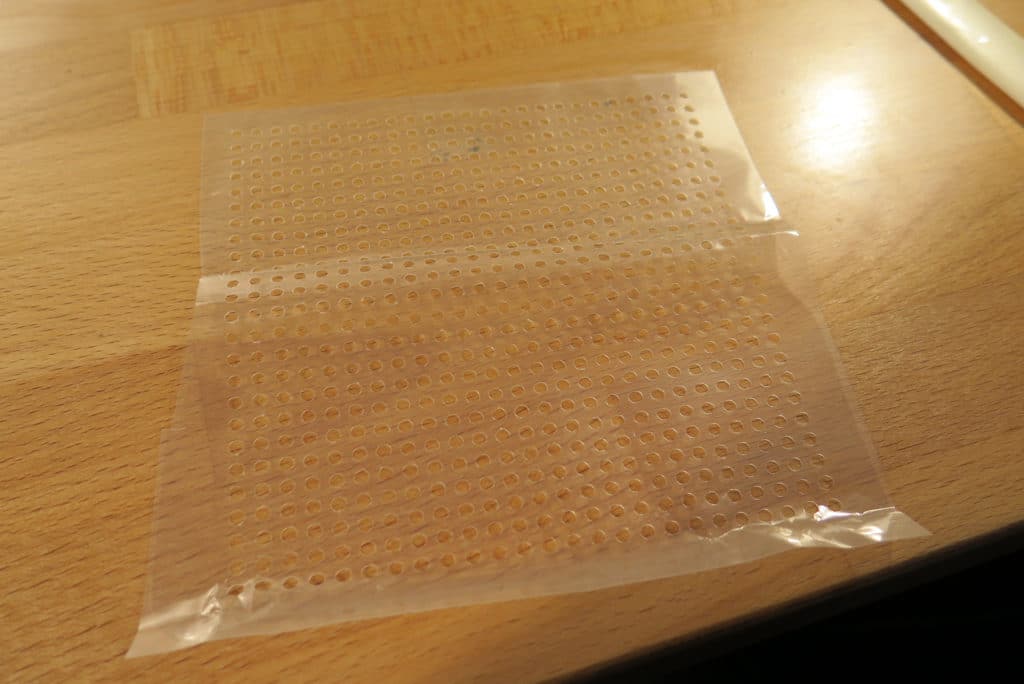

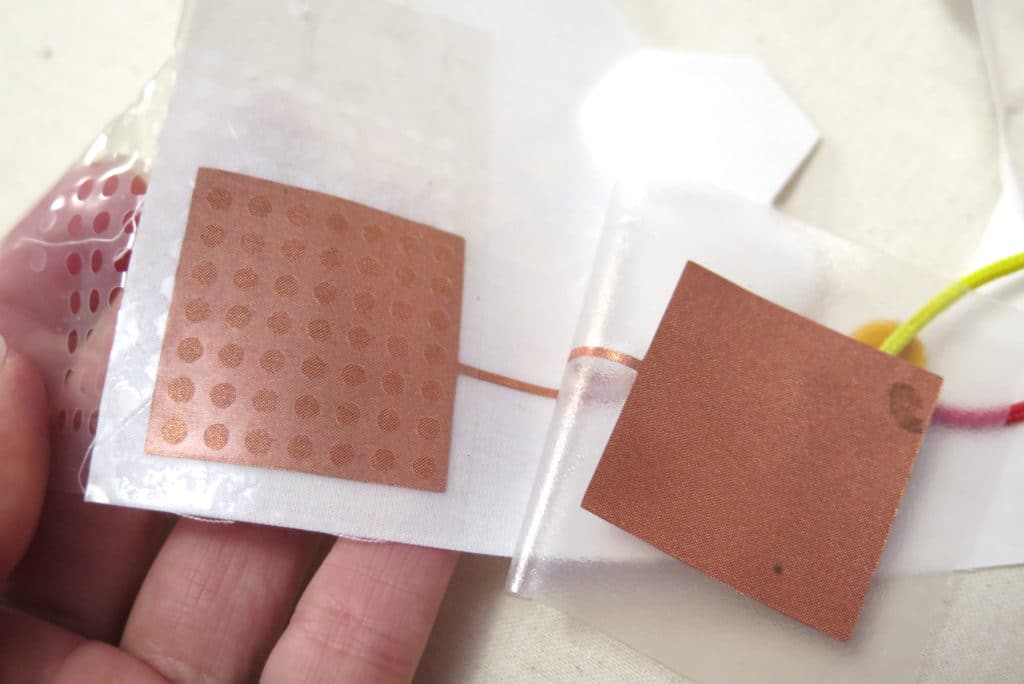

A pattern of circles cut from the silicone was decided on to replicate a net pattern. The ratio of open area vs. solid area will be beneficial to adjust for sensitivity. The thickness of the silicone will also be a factor affecting sensitivity.

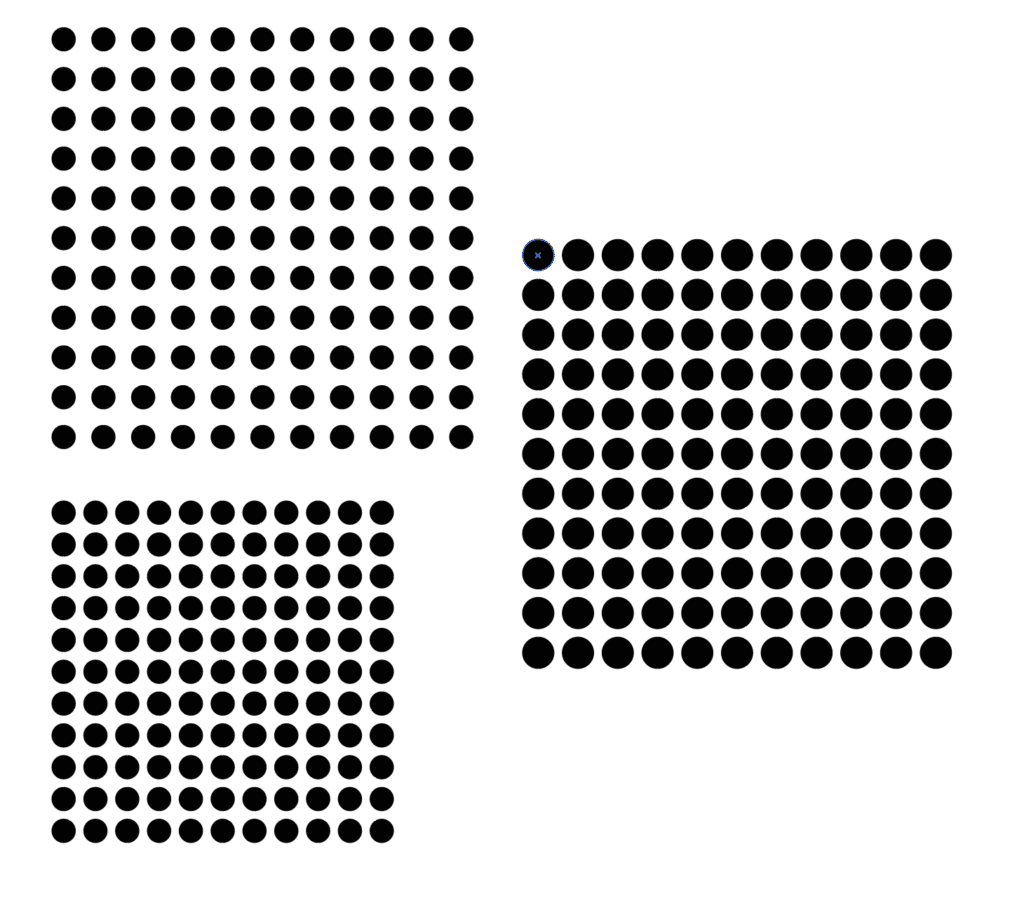

Getting the pattern right is the real challenge. Screenshots of a dot pattern using 3 mm – 4 mm circles with 4 mm – 6 mm spacing.

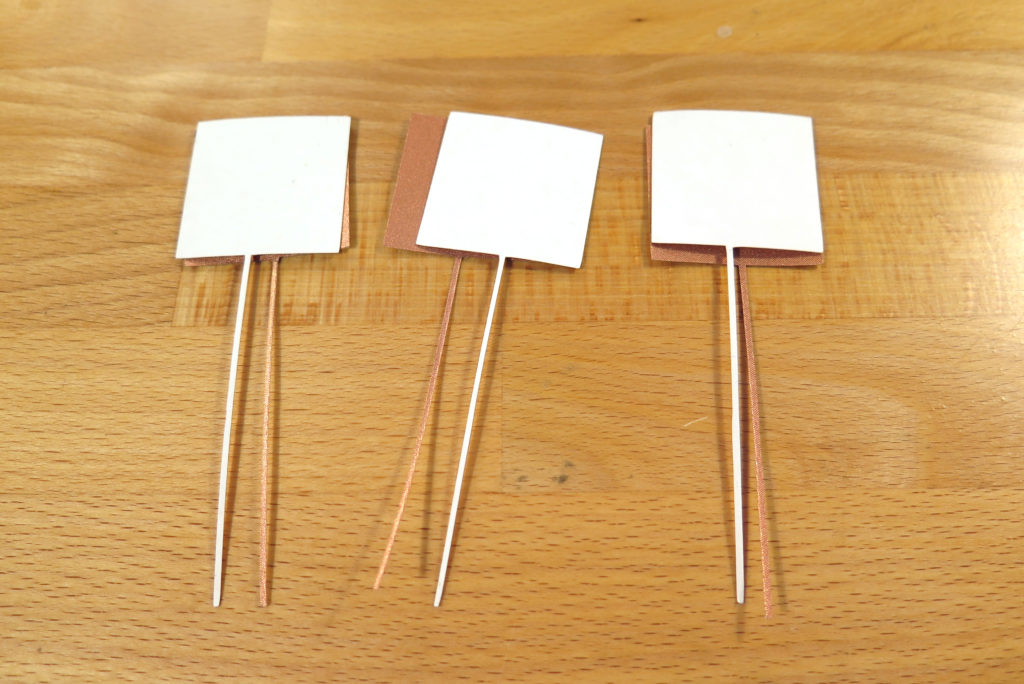

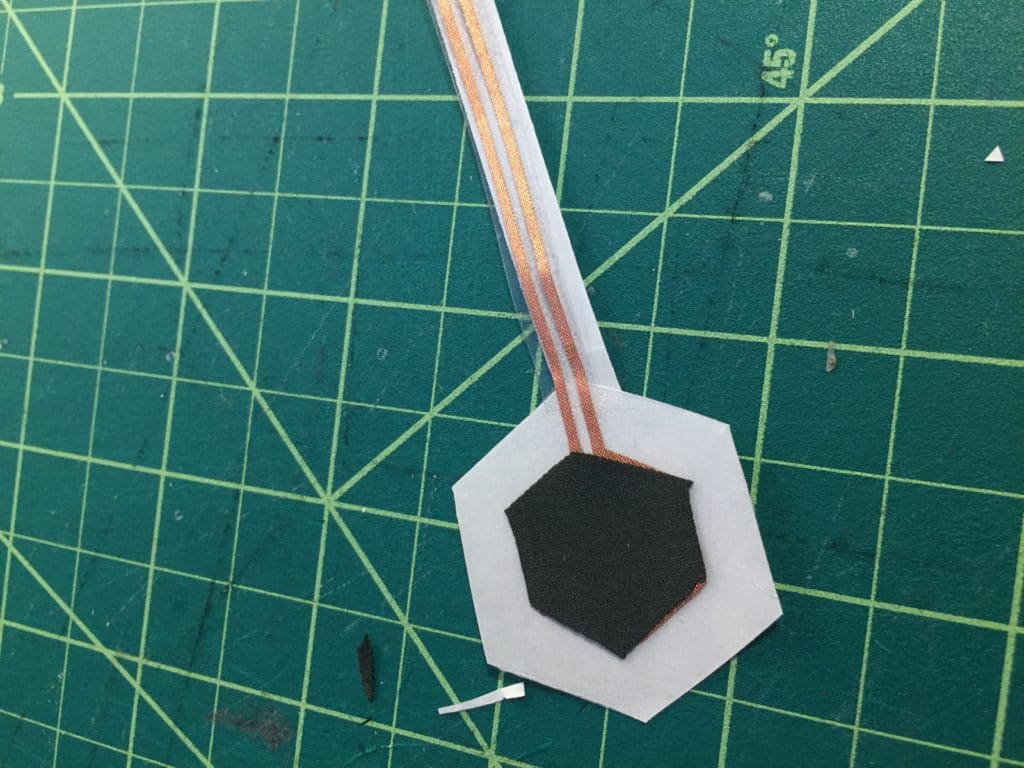

Rectangle Switch

The original hexagon switch designed for the kit has two things about the design that I wanted to correct:

- The intended intention of the hexagon shape was to save material when cut. This became moot when a lead was added to the contact so they were cut at one piece. Perhaps a tessellated pattern of them combined can be figured out later…

- They may not last when ironed on. The interdigitated break in the two contacts could allow the hot-melt adhesive that is also laminating the switch to seep through and transfer to the layers underneath.

- The net may not offer enough surface area between the contacts. The lines that the mesh is made from are very thin that I’m afraid over time it may lose its purpose of keeping the contacts apart after heating and/or flexing. Plus silicone has a higher resistance to heat generally being rated for keeping it properties up until 570º F, nylon going up to about 390º.

Did it work? So far, so good. I’ve made three and they work nicely using a pattern of holes 3 mm in diameter and 5 mm apart – center to center, cut from a 0.1 mm silicone sheet. Long term testing still needs to be done. I plan on having Monique test them with her cursor mover setup.